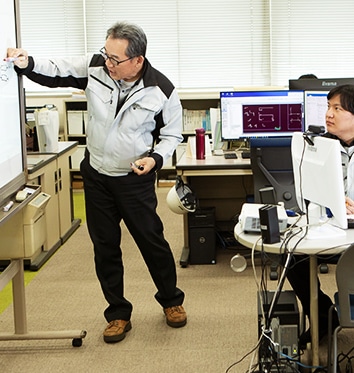

We provide a full range of services from gear unit design to machining, assembly, commissioning, shipping, and after-sales follow-up and realize high-quality proposals.

STRENGTH

Based on the trust and achievements accumulated from our more than 100 years in business, we design, machining, assembly, and test operation in-house, and manufacture high-quality gear units. Even after delivery, we provide after-sales service that promptly responds to customer needs.

SERVICE

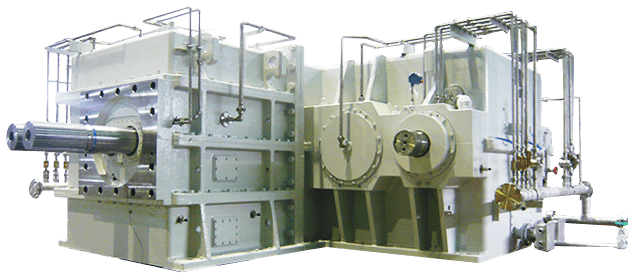

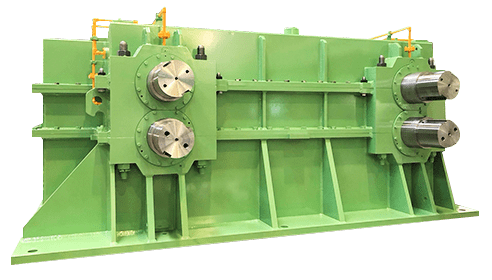

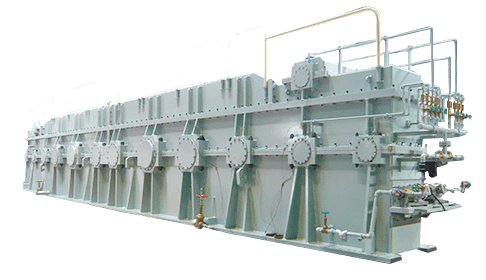

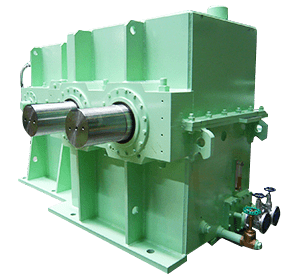

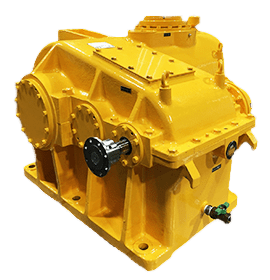

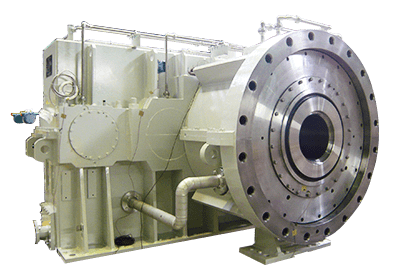

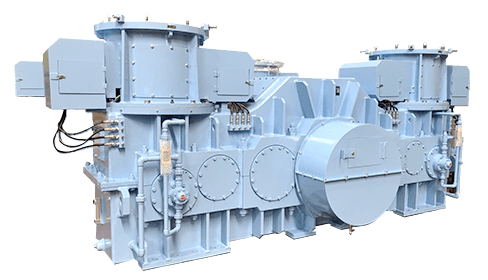

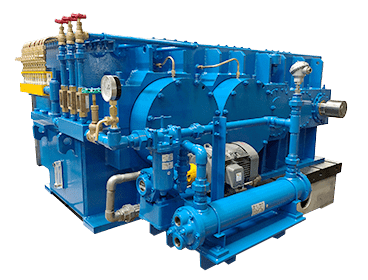

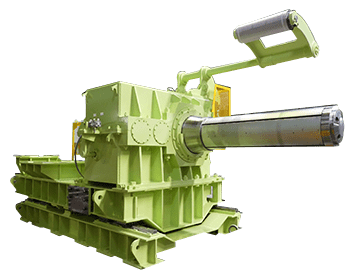

We provide integrated services from design, machining, assembly, and test operation for large industrial gears for plastic machinery, steelmaking machinery, and transport equipment. We also provide after-sales service.

PRODUCT

We produce gears for a variety of large industrial machinery, including the world's largest class of ultra-large gears.

RELIABLE AFTER-SALES SERVICE

Please feel free to contact us for any repairs or malfunctions of your gearing equipment.

MORE DETAILS ABOUT AFTER-SALES SERVICE